The enduring quality of harvested grain stands as a paramount consideration, intricately intertwined with both its moisture content and the temperature achieved during the storage process. In the climatic conditions of Scandinavia and the broader northern hemisphere, the post-harvest moisture content of grain typically spans a range of 15–45%. This wide variance necessitates strategic interventions to enhance the grain's keeping quality. Natural drying processes, inherent to the region, encounter limitations, as the prevailing climatic conditions during the harvesting season often result in relative air humidity levels soaring to 80–90%.

Given these challenges, achieving sufficiently low moisture content figures becomes a formidable task without the integration of auxiliary equipment. The imperative, therefore, is to employ diverse methods that enhance the keeping quality of the grain. Established techniques encompass a spectrum of drying methodologies and, albeit on a smaller scale, the utilization of freezing processes for grain preservation.

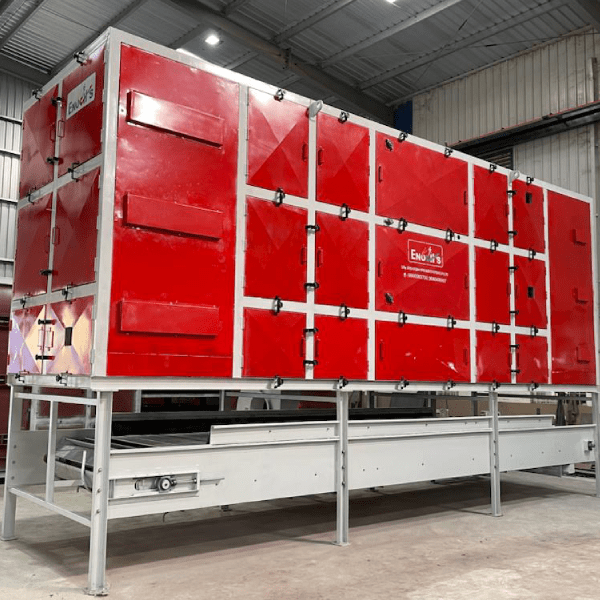

At the core of effective drying methods lie specialized dryers that orchestrate robust air flows circulating through the grain batch undergoing drying. This intricate dance of air is subsequently discharged into the atmosphere, facilitating the dissipation of moisture from the grain. Notably, the augmentation of moisture removal is achieved through the elevation of the grain's temperature during processing. To further refine the homogeneity of drying quality, innovative approaches involve the circulatory and cooling measures applied to the grain throughout the drying process.

In essence, the symbiotic integration of technological methodologies, such as specialized dryers, is imperative in navigating the challenges presented by the climatic conditions of the northern hemisphere. These advancements not only ensure the preservation of grain quality but also underscore the intricate balance between moisture content and temperature regulation, contributing to the longevity and integrity of the harvested yield.